Depending on who you ask, the 3D printing industry had a value of between 10 and 20 billion dollars in 2022. This figure is set to grow significantly in the coming years so this may be the best time to start your own 3D printing business.

There are plenty of businesses that you can start around 3D printing. A Print-on-demand service is a common choice, but the landscape of 3D printing businesses is wider than many makers realize.

Product manufacturing research could be a hidden gem in today’s additive manufacturing landscape. For the right makers, it could be the right business.

What is Product Manufacturing Research?

In 3D printing, product manufacturing research is the process of identifying the best way to print a product design.

In traditional manufacturing, this is handled during the process development stage. However, additive manufacturing is very different from traditional manufacturing in its operation and applications.

In a single step, 3D printing can achieve forms that would need several traditional manufacturing steps. This means the considerations when trying to figure out how best to manufacture a product using 3D printers are different.

What Are the Considerations When 3D Printing a Finished Product?

The number of random products we are able to successfully print makes 3D printing seem simple.

Products that are functional, work under niche conditions, are intended for mass production, or interact with human bodies, are harder to achieve.

Some important considerations when printing functional finished products include:

Best 3D printing process for manufacturing the product

Material properties (strength, chemical resistance, creep, etc.)

Product strength

Ease of printing

Preferred material

How to print the part/product with minimal supports

Minimizing post-processing

Ideal post-processing solution

Ideal print settings (speed, nozzle size, retraction)

Use of enclosure, etc.

These considerations serve two important purposes:

Ensuring the 3D printed product serves its intended purpose as expected.

Ensuring the manufacturing process is efficient and repeatable.

Where is the Opportunity in All This?

Finding the answers to the above considerations can be expensive and time-consuming. It might also be a fruitless effort without the right experience/expertise.

Owning an in-house 3D printer can be advantageous for a company or business. However, knowing how to make the best use of these machines requires a time investment that some cannot afford.

Such companies will need external assistance to make products with niche manufacturing specifications.

Can You Be a Product Manufacturing Expert?

If you have been 3D printing for several years, there’s a good chance you have what it takes to be a 3D-printed product manufacturing expert. The following experiences can make you highly effective in this role:

Working with a wide range of 3D printing machines.

Using different types of 3D printing technologies, e.g., FDM, SLA, SLS, etc.

Printing with a wide range of materials.

3D printing using unique or difficult-to-print materials e.g., carbon fiber-infused filament, PC, nylon, PP, etc.

Printing functional parts or products with features that are hard to print.

Testing functional 3D printed parts.

Working with different slicers.

Printing your own designs.

These experiences can enable you to quickly identify how to 3D print a product for optimal results. They can also help you to identify design features that will hinder the manufacturing process.

Why Could Product Manufacturing Research Be the Next Big 3D Printing Business?

Finding a design online and printing it oversimplifies the effort it takes to get a good print. Many of these designs are optimized for standard settings using materials like PLA that are easy to print.

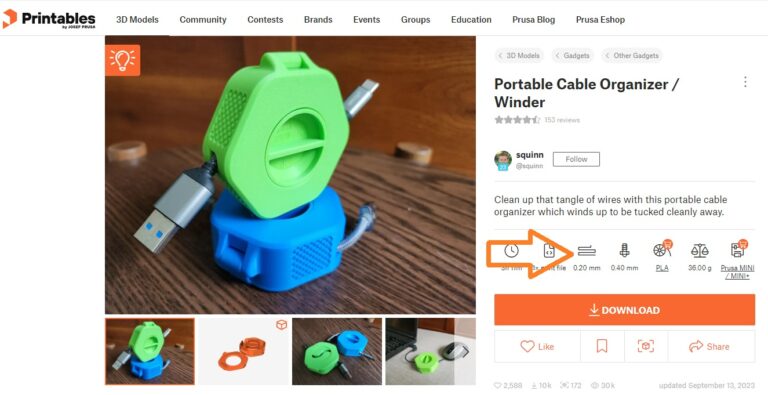

Other makers take the extra step of providing the exact print settings you need to get good printing results as shown below.

When you start designing and printing your own parts, you may realize that identifying optimal printing parameters takes a lot of time and material.

This time and material cost goes down eventually, but this requires a lot of hands-on experience.

As more individuals or companies uncover their need for 3D printed products, some will want to keep the manufacturing in-house. However, many will also realize that it will be faster and less expensive to rely on someone else to identify the parameters they need to get the best printing results.

Is Product Manufacturing Research the 3D Printing Business For You?

Product manufacturing research can be a great 3D printing business for someone with a lot of 3D printing experience. Thanks to your experience, you can get the right answers faster than clients with less 3D printing experience.

For some companies, developing the expertise needed to get the best out of their printers in-house will not make financial sense. Hiring a permanent employee may be challenging too, unless 3D printing becomes a key part of their operations.

Therefore, there is a gap between owning a high-quality 3D printer and getting good results for a specific print. You can use your years of experience and knowledge of what works, what doesn’t work, and what works best, to fill this gap.