Not every infill pattern is equally strong. As a result, many makers want to know what the strongest infill pattern is.

This question seems like it should have a direct and obvious answer but this is not the case. From an engineering standpoint, there could be more than one answer. From a practical standpoint, the answer may not even matter.

In this article, we will try to answer the question of what the strongest infill pattern is, according to a few recent studies. We’ll also explore why the issue of the strongest infill pattern can be controversial and why it may not be significant when we want strong 3D prints.

Which is the Strongest Infill Pattern?

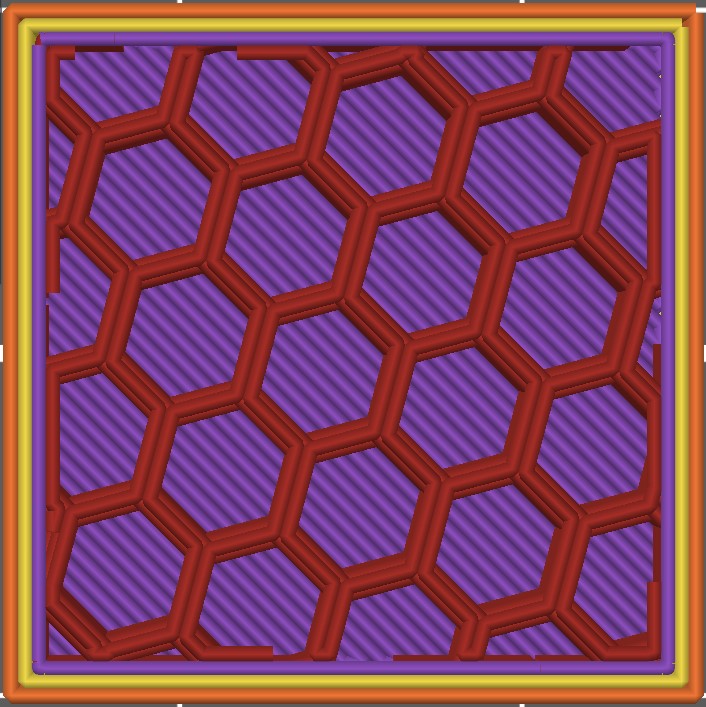

Although there is no consensus on the matter, the Honeycomb pattern may currently be the strongest infill pattern based on the results of several scientific studies.

In one study the compressive strength of four infill patterns were compared – triangle, honeycomb, rectilinear, and line. The honeycomb infill pattern had the highest values of peak strength in this study. The strengths were being compared at four different infill densities.

In a second study, the tensile strengths of five infill patterns were compared – Hilbert Curve, Gyroid, Honeycomb, Stars, and Gyroid. The honeycomb pattern emerged as the strongest, followed by the honeycomb 3D infill pattern.

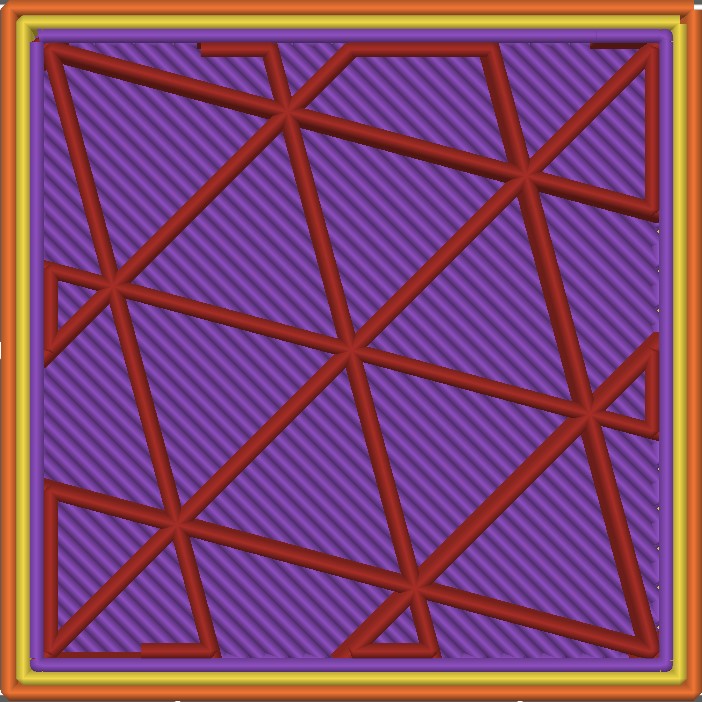

In a 3rd study, the compressive strengths of 14 infill patterns were compared. The cross, grid, and triangles pattern emerged the strongest, with 2D patterns generally outperforming 3D infill patterns. It should be noted that neither the honeycomb nor the honeycomb 3D infill pattern were part of this test.

The Challenges in Determining ‘The Strongest’ Infill Pattern

At this point, you may already have some idea of why it is challenging to state that one infill pattern is definitely the strongest. To make it more confusing, other voices in the industry claim the strongest infill pattern is either the triangles or tri-hexagon pattern.

The clash of experimental methodologies, what makes sense ‘mathematically’, and common lore put an asterisk on any claim that one infill pattern is the strongest.

Additionally, the tests above only discuss strength in tension and compression. This question gets further complicated when we include shear strength, flexural strength, strength in torsion, and impact strength.

This isn’t to say that there is no strongest infill pattern. However, unless there is uniformity in testing, the throne of the strongest infill pattern will remain unfilled. Additionally, there’s also a chance that one infill pattern will not be the strongest for every single type of strength.

How Much Does Infill Strength Matter Anyway?

This may be the most important question in this article. You might assume that the stronger an infill pattern is the better. However, many experts believe that although there are significant differences between the strength of different infill patterns, choosing one infill pattern over another may not significantly impact the strength of the part.

There are different ways to get a strong 3D print. Some approaches you can choose include:

- Printing using a stronger material

- Orienting the part differently on the print bed

- Altering the dimensions of some parts of the print

- Adopting a hybrid approach, e.g., using inserts

- Adding more shells to the printed part in the slicer

- Using higher infill densities, etc.

Many of these approaches are considered to have a more significant impact on the strength of the final print compared to the choice of infill pattern. Is it a coincidence that the honeycomb pattern also requires more material than other patterns at the same infill density?

During my time working with a 3D printing company, poor infill strength was never the factor that made the manufacture of a product less feasible. The question of the strength of printed parts was typically addressed by choice of material. Squeezing in a little extra strength by changing infill patterns was never a thing.

3D Printing Patterns for Practical Prints

Many makers get away with using some of the more basic infill patterns for their prints. These are patterns such as rectilinear and grid. These can be printed fast while offering adequate levels of strength.

The honeycomb and honeycomb 3D infill patterns may be among the strongest but the additional strength is rarely worth the extra material and time needed to print them. In practice, they are good for translucent prints where the infill pattern will be visible from the outside.

The gyroid pattern is favored when the goal is to achieve an aesthetically pleasing top surface. The concentric pattern can be a good choice for flexible parts due to the pattern of space they create inside the part.

What Is Infill Good For Anyway?

The difference between the strength of two infill patterns may be negligible, but the difference in strength between a part with infill and one with no infill is significant. This means that overall, any infill pattern you choose will contribute to the strength of the printed part.

Secondly, infill makes parts more printable. During printing, infill supports the walls and the top surfaces of the printed part. Without infill, these sections would collapse or deform under their own weights leading to failed prints, dimensional inaccuracies, or poor print quality.

Infill can also contribute to aesthetics especially when using translucent filaments that show the inside of printed parts.

In Conclusion

The question of what the strongest infill pattern is has not been conclusively answered but the honeycomb pattern has made a strong case for itself so far. Unfortunately, it’s also one of the slowest infill patterns to print.

Ultimately, many makers now believe that changing infill patterns is far from the most effective approach to achieving stronger strength characteristics. Adding more shells, and using higher infill densities are just two of several approaches that could yield better results.

Infill is an important factor in 3D printing and there are good reasons to choose one infill pattern over another. Achieving higher strength may not be one of these reasons.

Author's Note

This has been one of the more challenging articles I’ve had to write, but I also believe it is necessary to weigh in and give a perspective from a practical 3D printing point of view.

Just as with speed, the issue of the strength of 3D printed parts can be overemphasized when in fact, it is not a challenge that comes up often in real-world 3D printing. The issue of how strong a printed part needs to be is typically covered by the choice of material.

These materials have a ceiling and this means that 3D-printed parts can only be as strong as the base plastic material allows. This also means that in applications where plastic is the default material, a 3D printed is often strong enough to get the job done without you having to sweat over two different infill patterns.

There are infill patterns that are appreciably weaker but these are not the default and you can easily avoid ever using them. 3D printing is not a single-factor activity. Strength is one of these factors but one you’ll, probably, rarely agonize over unless you forget that plastic is plastic.